Diamond-like or Hard Carbon Coating

| Download Optical Coatings Datasheet (PDF, 7 MB) |

Diamond-like coating (DLC) or Hard Carbon Coating seems to be the most robust of all optical coatings. It is extremely resistant to salts, acids, alkalis, and most organic solvents. High mechanical hardness and low coefficient of friction make this film extremely resistant to abrasion. DLC has very good adhesion to germanium and silicon.

This coating is more often used on the outer surfaces of silicon and germanium optics of thermal imagers used in military equipment and/or operating under extreme climatic conditions. DLC protects external optical surfaces from the abrasive action of dust particles in the air, from sea water and salt, from engine oil and fuel, high humidity, improper handling etc.

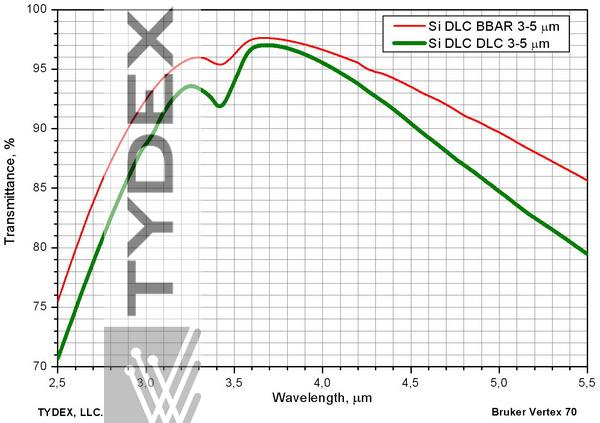

The film is characterized by moderate absorption and scattering levels throughout the entire IR spectral range. Index of refraction of the diamond-like film in the IR is about 1.95. That is why DLC film, applied by special methods, combines outstanding protective properties with a good antireflection effect.

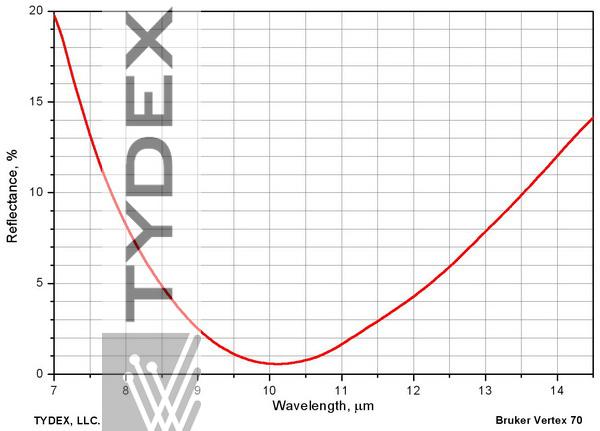

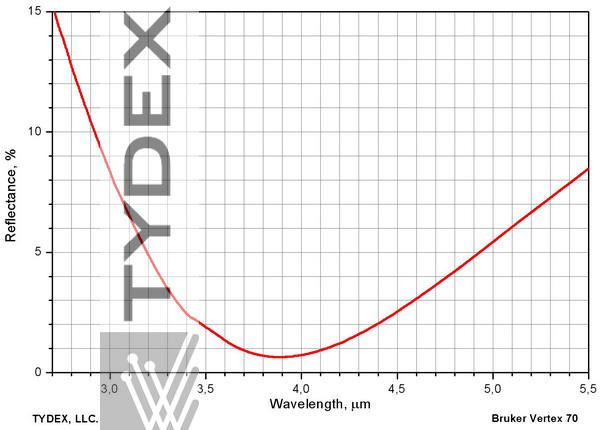

Being a single-layer coating, it can be optimized for a specific wavelength range (usually 3-5 or 8-14 μm bands) by adjusting layer thickness.

Fig. 2. Reflection of a DLC-coated germanium part.

Specification

| Chemical Properties | |

| Composition | carbon, hydrogen |

| Structure | A composite of sp3-hybridized (tetragonal diamond-like lattice), sp2-hybridized (trigonal graphite-like lattice) and amorphous carbon |

| Reactivity | Inert to acids, alkalis, solvents, salts, water and other reagents at ambient temperature. Combusts above 400°C |

| Physical Properties | |

| Density | 1.8-2.1 g/cm3 |

| Specific thermal conductivity | 10 W/cm × K |

| Thermal expansion coefficient | 9 × 10-6/°C |

| Resistivity | several MOhm × cm |

| Dielectric constant | ~ 4-11 |

| Permeability | Impenetrable to hydrogen and other gases |

| Optical Properties | |

| Optical transparency | Near to middle IR |

| Refractive index | 1.85 - 2.0 |

| Other Properties | |

| Operating temperature range | from -60°C to +400°C |

| Biological compatibility | Does not cause cellular breakdown or inflammation |

| Durability | Good adhesion to substrate, resistant to hard abrasion and mechanical impacts, high humidity, high and low temperatures, heat shock, saline vapors, saline solutions, insoluble in water, resistant to atmospheric condensation, dust and sand, some acids, lube and fuel oils per standards: MIL-C-675C, MIL-STD-810 |

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...